concasseur de processus chimique

-

lo que es diapositivas ppt trituradora de mandíbula

-

broyeur vertical à reconstruire

-

technologie de concasseur à cône au kenya

-

convoyeur 224 bande pour minerai

-

raymond broyeurs à charbon

-

Les Fabricants De L Usine De Tubes Japonais

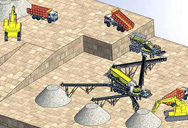

Application of Mobile Primary Crushing and Belt

2024.5.1 ABSTRACT. This paper briefly reviews the background of mobile primary crushers and their current main areas of application. The benefits of applying mobile primary crushing and belt conveying systems are analysed. The impacts of applying such systems to different steps of the mine process are discussed, including mine development and

Bavarder sur Internet

Going underground: Jaws or a primary gyratory?

2014.5.8 Setting up an underground primary crushing plant requires careful planning. Here's how to choose between jaw and a primary gyratory crusher. The required capacity defines the size and type of crushing

Bavarder sur Internet

Primary Crusher Optimisation for Improved Comminution

2024.5.1 DEFINITION. The primary crusher selection is the key to the success of any mining operation that involves the reduction in size of the ore. The crushing plant can be provided with almost any type of primary rock crusher. The rock/ore determines the type of crusher. The plant capacity determines the size of the crusher.

Bavarder sur Internet

Six ways to take primary crushing underground - Australian

2014.8.1 1. Sizing the plant. Real estate in an underground mine is not cheap, so the design of primary crushing plants faces more limitations underground than on the surface. However, the primary crushing and transportation of ore to the surface are often the determining factor that decides on the capacity of the mine.

Bavarder sur Internet

Crushing Plant Design and Layout Considerations - 911

2016.2.24 Mine haul-truck capacity is an important factor at primary crusher installations, because it is cost-effective to integrate truck cycle time at the crusher station with mine/shovel operations. If a primary crusher dump pocket is undersized and unable to handle the mine’s trucks, then operators must slowly meter the ore into the receiving

Bavarder sur Internet

Primary Crushing Station SpringerLink

2023.1.31 Underground primary crushing station (Fig. 3) is generally fixed. It is usually located next to the skip shaft and is characterized by long service life, long infrastructure time, etc. The main equipment of the primary crushing station includes a crusher, feeder, dedusting apparatus, crane, etc.

Bavarder sur Internet

GitHub

sbm underground primary crusher plant designAspects Of Underground Primary Crusher Plant Design aspects of underground primary crushing plant design.Apr 10,2013 Crushing Plant D

Bavarder sur Internet

Choosing the right primary crusher for your

Sep 27, 2019. Choosing the right primary crusher for your aggregate application. A primary crusher is the driving force of the success of your plant. Here is what a successful process of choosing a primary crusher

Bavarder sur Internet

New large-capacity primary crusher for above and

New large-capacity primary crusher for above and underground applications. 22.01.2021. Metso Outotec has launched an extension to it’s primary gyratory crusher range: The SUPERIOR™ MKIII 6275UG. The new

Bavarder sur Internet

en/161/kolkata underground crusher installation costs.md at

Host and manage packages Security. Find and fix vulnerabilities

Bavarder sur Internet

Going underground: Jaws or a primary gyratory?

2014.5.8 Selecting the right crusher. Jaw crushers are the most common solution in underground applications when the throughput is less than 1,000 tons per hour, depending somewhat on the scalping

Bavarder sur Internet

Mining crushers SuperiorTM MKIII Primary Gyratory

2022.12.28 Superior™ Primary Gyratory MKIII Range Perfect mix of experience and innovation 100+ years of proven experience, latest advancements in metallurgy and thousands of crusher installations around the world combine to create a Primary Gyratory crusher with the best performance, highest capacity and highest reliability.

Bavarder sur Internet

Portable Rock Crushers - 911 Metallurgist

2024.2.1 An admittedly unlikely example of a situation in which an impact type crusher could be successfully employed as a portable underground primary crusher might be described by the following conditions: (a) abnormally small ROM material suitable for impactor feed but too big to be conveyed. (b) very friable, non-abrasive feed, material.

Bavarder sur Internet

Underground Crusher Selection and Design - 911 Metallurgist

2024.5.13 Putting a primary gyratory underground is probably not recommended. You will find two significant issues. The first is that moving the smallest part from that crusher underground will challenge the undertaking because of weight and size. The smallest part for the largest jaw crusher is practical and much easier.

Bavarder sur Internet

Primary Crushing Station SpringerLink

2023.1.31 Underground primary crushing station (Fig. 3) is generally fixed. It is usually located next to the skip shaft and is characterized by long service life, long infrastructure time, etc. The main equipment of the primary crushing station includes a crusher, feeder, dedusting apparatus, crane, etc. The primary crusher is mainly divided

Bavarder sur Internet

underground ore crusher price

Crusher, Heavy-duty primary jaw crushers are installed underground for uniform size reduction before transferring the ore to the main centralized hoisting system.Chapter 6.3 COSTS AND COST ESTIMATION, unit costs for excavation, concrete foundations, and installations of piping, electric Cost of Primary Crusher ...

Bavarder sur Internet

Nordberg® C160™ jaw crusher - Metso

Nordberg® C160™ jaw crusher is designed to be extremely reliable. Its equipped to meet the expectations of customers who run their primary crushing plants 24 hours a day. Based on customer experience and comprehensive testing, the critical areas of Nordberg® C160™ jaw crusher are protected against wear. The vital parts are also quickly ...

Bavarder sur Internet

SUPPORT IN UNDERGROUND HARD ROCK MINES

2023.7.12 The choice of the type of support installed in a particular underground excavation depends upon the extent of the zone of loosened or fractured rock surrounding that excavation. A very crude guide to support selection is given in Table 1. Active rock reinforcement Underground mines use two principal types of rock reinforcement - tensioned

Bavarder sur Internet

Metso Outotec launches compact large-capacity primary crusher

2020.11.10 The crusher was born out of a need for a high capacity underground primary crusher that did not require a primary feeder, scalper, and the associated infrastructure therein. Minimizing the need for high cost stationary grids to control topsize underground was a requisite, and the large topsize acceptance was met with the UG

Bavarder sur Internet

Nordberg C130 STD Galadari Trucks Heavy

Nordberg® C130™ jaw crusher is easily installed in surface, underground or mobile applications. The pin and bolted structure enables that the jaw crusher can be swiftly disassembled and transported cost-effectively also

Bavarder sur Internet

primary crusher underground

The crusher was born out of a need for a high capacity underground primary crusher that did not require a primary feeder, scalper, and the associated infrastructure therein. Minimizing the need for high cost stationary grids to control topsize underground was a requisite, and the large topsize acceptance was met with the UG design.

Bavarder sur Internet

Metso Nordberg® C130™ jaw crusher Jaw crusher - Global-CE

The pin and bolted structure enables that the jaw crusher can be swiftly disassembled and transported cost-effectively also to the deepest mines. Any demanding primary crushing application; Surface and underground applications; Stationary, portable, and mobile installations; For hard rock, soft rock, gravel, slag, industrial materials

Bavarder sur Internet

Capabilities Experience - UCA

Primary Crushing Stations – UCA has installed new primary gyratory crushers, tipples, crusher feed pockets, and discharge pockets.. Crushed Ore Bins – UCA has installed crushed ore bins of various capacities.. Tramp Removal Areas – UCA has installed Tramp Removal Systems, including Apron Feeders, Picking/Collection Conveyors, Magnets and

Bavarder sur Internet

underground crusher installations - jakkalsvallei.co

Innovation delivers new approach to primary crushing. The ERC (eccentric roll crusher) is a hard rock crusher featuring a low-wear design and durable components that enhance efficiency, according to thyssenkrupp.Because of its flat, robust design with an integrated screen and high throughputs of up to 8,000 metric tph, thyssenkrupp says the

Bavarder sur Internet

underground crusher installations - penziongreen

underground crusher installations sol resinechThe Gyratory Crusher . underground crusher installations underground crusher installation costs Six ways to take primary crushing underground Australian Mining Jaw crushers are the most common solution in underground applications when the get more infoMay 20 32 A crusher is a machine designed to

Bavarder sur Internet

sbm/sbm underground coal primary crusher.md at master

You've already forked sbm 0 Code Issues Pull Requests Packages Projects Releases Wiki Activity

Bavarder sur Internet

underground primary crusher plant design

primary crusher for underground metal mine . used primary underground cone crusher plants UGB. Dec 28, 2016 ... Crusher Plant Design Figure 4 Jaw crusher underground crusher for mining for underground .

Bavarder sur Internet

Metso Nordberg® C80™ jaw crusher Jaw crusher - Global-CE

Nordberg® C80™ jaw crusher is easily installed in surface, underground or mobile applications. The pin and bolted structure enables that the jaw crusher can be swiftly disassembled and transported cost-effectively. Steel fabricated subframe for surface installations is available as option. Any demanding primary crushing application

Bavarder sur Internet

Compact, robust and high-performance: New ERC25-25

Semantic Scholar extracted view of "Compact, robust and high-performance: New ERC25-25 eccentric roll crusher revolutionizes primary crushing in under- ground mines. Kompakt, robust und leistungsstark: Neuer Exzenterwalzenbrecher ERC25-25 revolutioniert die Primärzerkleinerung unter Tage" by Piotr Szczelina et al.

Bavarder sur Internet

Primary Crushing: A Comprehensive Guide - JXSC

2024.2.23 Primary crushing happens when we take big rocks, even ones bigger than a meter, and make them into smaller bits. These bits are often between 150 and 200 mm. This step is very important. It makes the rocks smaller. This helps the next machines work better at crushing or grinding them.

Bavarder sur Internet

Six ways to take primary crushing underground - Australian

2014.8.1 Automation and centralised lubrication are cost-effective ways to improve the maintenance process. Underground plants generally operate unmanned, so make sure to utilise the automation and ...

Bavarder sur Internet

shibang/sbm crusher installation primary.md at master

sbm crusher installation primaryPrimary Shredders Reversible Shredders Williams Crusher Williams Patent Crusher offers a complete line of one way and reversible primary shredders.There are many advantages to Williams’’

Bavarder sur Internet

underground primary crusher powerpoint

underground primary crusher installations - Solutions - underground crusher underground mine. going to talk about jaw crushers in this particular presentation. 5. • Jaw Crusher • Jaw crusher is a type of crusher which produces coarse particle.MSHA offers a wide variety of mine safety and health materials to assist trainers and mine ...

Bavarder sur Internet

UNDERGROUND INSTALLATIONS - South Australia

Our comprehensive services make UGI your one-stop-shop for all your directional drilling and civil construction needs. Underground Installations provides vacuum excavation, underground utility location and installation, directional drilling, rock sawing, backfilling, and more, across South Australia. The team at Murchison Grade Control provide ...

Bavarder sur Internet

Understanding Types of Jaw Crusher: A Comprehensive

2024.2.6 Blake jaw crushers, also as double toggle jaw crushers, are characterized by the position of the pivot of the swing jaw, which is located at the top of the machine. This design allows for a larger feed size and a higher capacity, making it suitable for primary crushing. The motion of the swing jaw in a Blake crusher is predominantly vertical ...

Bavarder sur Internet

OneMine Transforming Underground Blasting Operations into Primary ...

2019.1.1 Purchase this Article for $25.00. There has been significant progress made with narrow vein gold mines in which a second option for crushing has begun to attract attention. To ensure the profitability of a mine that has based its economics on the absence of a crusher station, more than just best blasting practices are required.

Bavarder sur Internet

Primary Crusher - an overview ScienceDirect Topics

The primary crusher is located in the quarry and consists of a McLanahan 48″x72′ Shale King Crusher rated at 1,000 TPH (Tons Per Hour). The driving flywheel has a diameter of 2.5 meters and is motor driven through six v-belts. ... In clinker dispatch installations, screens are used for the removal of fine particles caused by abrasion or ...

Bavarder sur Internet

Nordberg® C96™ jaw crusher - Metso

Nordberg® C96™ jaw crusher is an all-round crushing machine well equipped to serve in stationary and mobile applications both on the ground and underground. Generally used as a primary crusher, Nordberg® C96™ can also be utilized in later stages of the size reduction process. Contact our sales experts. Extremely reliable. Outstanding ...

Bavarder sur Internet

Types of Crushers: What You Need to Know

2023.8.2 There are lots of different kinds of crushers from jaw crushers to impactors and cone crushers. Crushing is an versatile process and the kind of crusher you need depends on the 'stage' of crushing. The three main stages of crushing are primary, secondary, and tertiary - all of which have their own unique benefits.

Bavarder sur Internet

Articles liés

- la consommation d'énergie de rotation de la sécheuse

- calcul de la charge de circulation du broyeur

- cot de la construction de cimenteries

- coût des installations et de machines pour la pierre concasseur

- l'utilisation de fines de minerai de manganèse en chine

- la production chinoise de clinker

- usine de concasseur tph en pierre de seconde main

- moulins et fours à cimenterie

- cimenteries en maharashtra

- mobiles de concassage perou

- pierre de chaux traitée

- trituradora de doble rodillo para la arena que hace la

- xsd roue laveuse de sable

- application des concasseurs de pierre

- carrière de prix du pétrole

- Moulin a barre de charbon pour la vente

- séparation de sol calcaire et la machine

- centrale à béton mobile

- pierre entreprise de machines de concassage

- concasseur terme par verge cube

- fabricant de convoyeurs a bande

- cs concasseurs afrique du sud

- concasseur à cône série s pour concassage fin

- pierres precieuses topaze en pierre

- concasseur de pierre de l alberta

- machine de moulin 2c william modèle standard

- machine enrichissement de manganèse

- mini broyeur de pierres avance

- nouvelle machine de broyage de lavage et de séchage

- emplois de contremaC3AEtre d usine de concasseur