utilizó venta planta de cemento de méxico

-

usine de fabrication de blocs

-

maison construite broyeurs à marteaux afrique du sud

-

Broyeur De Pierre En Allemagne

-

conception cône concasseur de roches

-

vente de broyeur de pierres

-

que una trituradora de cono

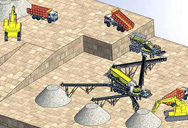

Crushing Plant Design and Layout Considerations - 911

2016.2.24 There are three main steps in designing a good crushing plant: process design, equipment selection, and layout. The first two are dictated by production requirements and design parameters, but the layout can reflect the input, preferences and operational experience of a number of parties.

Bavarder sur Internet

(PDF) Optimization Capabilities for Crushing Plants

2022.4.26 The objective of the crushing plant operation for the aggregates industry is to supply specific size fractions of rock material for infrastructure development, while the objective in minerals...

Bavarder sur Internet

Optimization Capabilities for Crushing Plants - Chalmers

a crushing plant operation consisting of rock size reduction (comminution) and particle size separation (classification) processes. The objective of the crushing plant operation for the aggregates industry is to supply specific size fractions of rock material for infrastructure development, while the objective in

Bavarder sur Internet

Optimization and Simulation of Operation Performance in Crushing Plants ...

2019.10.25 This research includes optimization of aggregate production of the stone crushing plant using fuzzy modelling. The investigation includes onsite aggregate testing and fuzzy logic implementation. Fuzzy modelling is a type of computerized reasoning used to simulate the real plant operation. In this work, a lot of agent degree information for ...

Bavarder sur Internet

Construction Working and Maintenance of Crushers for

(Edition: December 2018) Content. Crushers for Bulk Materials. Crushers and breakers are used to reduce size of mined and quarried material for further processing or to size suitable for the intended end use. The goal of a crusher is to crush the given material in to the material with certain size and shape.

Bavarder sur Internet

Trade-Off Curves for Performance Optimization in a Crushing Plant

2023.9.23 One common approach to producing the desired product is by varying the operation settings of a crusher in a crushing plant. However, knowledge of differences in operational performance for changing feed conditions in the circuit is required.

Bavarder sur Internet

Field monitoring and performance evaluation of crushing plant operation ...

2014.5.14 Crushing plants are of great interest in reducing a particle size of rocks and ores as milling operations need to consider sustainable development. Since the crushing plants operate under harsh...

Bavarder sur Internet

Crushing and Screening Handbook - AusIMM

2021.6.24 Complete stationary or mobile plants Besides off ering complete stationary instal-lations, Metso is the pioneer in fully mobile in-pit crushing operation. Integrating two or three mobile crushing plants combined with a mobile screen and a mobile conveying system results in improved effi ciency and end-product

Bavarder sur Internet

Factors affecting the performance of crushing

2014.1.1 This paper presents factors affecting the overall performance of the Çayeli mine crushing plant operation by addressing the critical design parameters as well as the consideration of ore...

Bavarder sur Internet

How Does A Stone Crushing Plant Work - aimixgroup

6 天之前 Here is a detailed explanation of how the stone crushing plant works. 1. Feeding. The working process of the stone crushing plant starts from the feeding. The raw stone is fed into the crushing plant by means of transport equipment such as trucks or conveyor belts. Before crushing, it needs to remove dust and impurities from the raw materials ...

Bavarder sur Internet

(PDF) Crushing Plant Dynamics - ResearchGate

2015.10.15 The capability of process simulation to replicate crushing plant performance and implementation in fullscale plant design and operation has increased over the past couple of decades [9, 10, 20,21 ...

Bavarder sur Internet

Optimization and Simulation of Operation Performance in Crushing Plants ...

2019.10.25 This research includes optimization of aggregate production of the stone crushing plant using fuzzy modelling. The investigation includes onsite aggregate testing and fuzzy logic implementation. Fuzzy modelling is a type of computerized reasoning used to simulate the real plant operation. In this work, a lot of agent degree information for

Bavarder sur Internet

FIELD MONITORING AND PERFORMANCE EVALUATION

2023.12.30 Table 1 lists the crushed ore according to campaign type and distribution. The use rates of Spec, CO, BYO, and BCO ores are respectively 29%, 42%, 10%, and 19%, taking into consideration the ...

Bavarder sur Internet

Field monitoring and performance evaluation of crushing plant operation

This is mainly due to a number of sharp metals or objects, which Field monitoring and performance evaluation of crushing plant operation 625 are directly dropped on the conveyor by causing damages. To prevent this happening again, a rip detection system is installed in this belt conveyor. In addition, the double deck screen costs are ...

Bavarder sur Internet

Evaluation of blast efficiency in aggregate quarries: facts and ...

2021.3.13 Quarry blasts and seismicity. Blast operation creates both elastic and inelastic deformation within the nearby rock mass. A seismic event is a rapid inelastic deformation that occurred within a specified volume of rock (Ma et al. 2015).Regulatory authorities usually monitor blasts in quarries on the scheduled date of the operations by

Bavarder sur Internet

Crushing Plant Installation, Operation and Maintain - JXSC

To ensure higher production efficiency and longer service life, plant manufacturers must do a good job of maintenance. 1. Dearing maintenance. Bearing parts of crushing equipment is more easily damaged. Making sure the service life of bearings needs to add lubricating oil and grease. 2. Daily maintenance.

Bavarder sur Internet

CRUSHING PLANT PROCESS OPTIMISATION

2024.5.1 differences that affect the design of the crushing plant both in terms of technical performance and cost of operation. The crushing stage design will for example affect aspects such as: Equipment size, number of equipment, reduction ratio, build complexity, wear part consumption, fi nal product extraction possibilities, product

Bavarder sur Internet

Conduct Crushing Screening Plant Operations - CMPA

RIIPRO301A — Conduct Crushing Screening Plant Operations. RTO: Box Hill Institute of TAFE. Bookings: Diane Wilson – 03 9286 9711. Focus: This unit covers the conducting of crushing and screening operations on a work site. It includes the planning and preparation for operations; the operation and post operational procedures of fixed ...

Bavarder sur Internet

quarry operations - Traduction française – Linguee

De très nombreux exemples de phrases traduites contenant "quarry operations" ... crushing and screening plants: for contract [...] crushing and screening, quarry operations, minerals processing ... répertorier le type de pierre de chaque carrière et accorder un code de produit à chacune. maestro.ca. maestro.ca.

Bavarder sur Internet

Mastering Plant Operations (Complete Guide) FieldInsight

2023.9.22 The Significance of Plant Operations. Plant operations encompass the orchestration of various elements, from machinery and equipment to a skilled workforce and intricate processes. It’s the epicentre of production, where every component works in harmony to achieve production targets, maintain product quality, and ensure operational

Bavarder sur Internet

What Machines Do Stone Crushing Plants Need? Fote

2024.3.1 2. Gyratory crusher. A gyratory crusher is one of the most in-demand primary crushers for stone crushing plants. It can process rocks, metal ores, granite, and other solid minerals of medium to high hardness. Gyratory crushers may be huge and capital-intensive, but they excel in high-capacity operations.

Bavarder sur Internet

Stone Crusher Plant Design: Best Practices for Efficient Crushing ...

2023.2.28 Stone crusher plant design is a crucial factor in the efficient operation of the crushing process. The primary goal of plant design is to achieve the desired product size and capacity while balancing capital and operational costs. A well-designed plant will help minimize production downtime and reduce operating costs while maximizing production ...

Bavarder sur Internet

Crushing - Principles of Mechanical Crushing - 911

2016.1.12 Relation between Feed size and Shape. The greater reduction ratio the worse particle shape. Inter particle breakage improves shape. When crushing a bed of material weaker particles will break first. Flaky or elongated particles are weaker then round. Breaking round particles gives flaky material.

Bavarder sur Internet

Stationary Crushing Plants - CONMACH

Stationary crushing plants are machines used in sectors such as mining and construction to break down large and varied materials into smaller pieces. These facilities are designed to increase the efficiency of material processing and production processes, especially in large-scale projects. Known for their durability and high capacities, fixed ...

Bavarder sur Internet

Trade-Off Curves for Performance Optimization in a Crushing Plant

2023.9.23 The choice of re-crushing existing product fractions results in feed condition changes to the crusher. One common approach to producing the desired product is by varying the operation settings of a crusher in a crushing plant. However, knowledge of differences in operational performance for changing feed conditions in the circuit is required.

Bavarder sur Internet

Crushing Screening Plant - 911 Metallurgist

2016.7.12 Crushing Screening Plant. Methods used in Crushing Screening Plants on ore range from a simple combination of a grizzly and one crusher to an elaborate arrangement in series of grizzly, jaw crusher, screens, and rolls or cone crushers. Crushing is done underground at a few large mines. In general, the jaw crusher is the most suitable ...

Bavarder sur Internet

Crushing it: A Comprehensive Guide to Stone Crusher Plants

2023.2.28 Introduction: A stone crusher plant is a machine designed to reduce the size of large rocks, eliminate gravel, or rock dust to smaller sizes for various applications. These plants find application in quarrying, mining, construction, and recycling operations. Stone crusher plants consist of several components, including a primary crusher,

Bavarder sur Internet

Apa Itu Crushing Plant dan Bagaimana Peranannya Dalam ...

2023.10.8 Kesimpulan. Dari artikel diatas kita telah mempelajari hal-hal terkait dengan apa itu crushing plant, bagaimana proses kerjanya, manfaatnya, berikut dengan tantangan dalam penggunaanya. Dapat disimpulkan bahwa crushing plant adalah aset berharga bagi industri pertambangan, memainkan peran sentral dalam mengubah

Bavarder sur Internet

Factors affecting the performance of crushing

2014.1.1 In mining operations, the layout of crushing plants and ancillary equipment and structures is a crucial factor in meeting production requirements while keeping capital and operational costs to a ...

Bavarder sur Internet

How To Operate A Stone Crushing Plant Safely

2024.5.3 The crushing plant is the heart of the stone crushing plant and is responsible for crushing the raw material into gravel of the desired size. Depending on the different crushing principles and methods, crushing plants can be divided into jaw crushers, cone crushers, impact crushers, etc. After the raw materials are processed by the crushing ...

Bavarder sur Internet

Site Safety and Safer Aggregate Crushing

2019.9.11 Site Safety and Safer Aggregate Crushing Operations. 11 September, 2019. First published in the September 2019 issue of Quarry Management as Safe and Sound. McLanahan discuss the key priorities

Bavarder sur Internet

Stone Crusher Plants - Transform Stones Into Valuable

2024.5.14 60tph stone crushing plant for recycling construction wastes. APS-1548Y3 vibrating screen. APC-900Y compound cone crusher. APG-0724Z vibrating feeder. APJ-4060E jaw crusher. Max feeding size: 400mm. Finished particle size: screen size is 4800*1500mm. Yield demands: 60 ton per hour. Configurations: APG-0724Z (vibrating

Bavarder sur Internet

The Ultimate Guide to Designing an Efficient Aggregate Crushing Plant

2023.2.23 Introduction. An aggregate crushing plant is a machine that processes a wide range of raw materials into high-quality aggregate, which is used in a variety of construction applications such as roads, buildings, and bridges. Designing an efficient crushing plant is critical to achieving maximum productivity, profitability, and sustainability

Bavarder sur Internet

Mineral Processing Plants in UAE (plan, design and install)

2020.7.26 With over 150 highly skilled engineers, designers, and fabricators, we can install a plant that meets your specifications globally. We have constructed nearly 50 turnkey high-capacity plants in the MENA region. Custom components include various crusher types, screen sizes, and output volumes up to 3,500 tonnes per hour.

Bavarder sur Internet

Tactics for Optimizing Crusher and Mill Efficiency: A Guide for Plant ...

2023.5.19 Use the right type and size of the crushing chamber: The crushing chamber is the space where the material is crushed. Different types and sizes of crushing chambers can be used to optimize efficiency for specific applications. For example, a short head cone crusher with a tight, crushing chamber may be better suited for grinding fine

Bavarder sur Internet

Crushing Plant - an overview ScienceDirect Topics

Most production mining operations aim for a round-the-clock operation, seven days a week, 365 days a year. In practice, semi-autogenous milling facilities run at about 95% capacity (run-time) with an efficient crushing plant running at around 85% (Jenike and Johanson, 2022). These figures should thus be extremely near to, if not greater, the ...

Bavarder sur Internet

Mass balance control of crushing circuits - ScienceDirect

2019.5.1 A crushing circuit comprises a combination of unit operations for crushing, screening, conveying, feeding, and intermediate storing. Different circuits are typically separated with stockpiles; in smaller mobile plants, the processed material flows through an uninterrupted chain of several crushing stages, whereas in larger plants, stockpiles ...

Bavarder sur Internet

Crushing Plant Design and Layout - Yeco Machinery

A well-designed plant layout balances the capital versus operating cost over mine life. Buildings, infrastructure, and major equipment items, represent the major cost elements of a crushing plant. Yeco Machinery’s engineers will prepare a layout that suits the design criteria, flowsheet and selected equipment in the most economical possible ...

Bavarder sur Internet

Articles liés

- l'équipement minier en pierre de granit à vendre

- broyeur à billes pour la dispersion de nm griding humide

- x moulin à circuit fermé

- dragon de ncasseur de matériel

- 250x400 ukuran concasseur, quartz moulin de meulage

- ciment matériaux auxiliaires de broyage de ciment de l'usine de broyage

- concasseur à mâchoires stamp

- chaine de fabrication de béton

- moulins minerai de zircon

- dolomite amende prix de concasseur

- calculatrice internationale de formule de gravité

- concasseur à mâchoires portable dans les philippines

- petit laminoir vertical

- fabricant de billes de broyage en tiges crushersprodusen

- tracked mobile crushers

- boîte de vitesses avec la zone de la broche moulin vertical

- pour magking minerai de gypse pour poudre de gypse

- broyeur de calcaire pour la location en inde

- machines de sable du lit de la rivière

- concasseur marque broyage de glace

- meulage des pointes de carbure

- tph cne concasseur vendre l inde

- coût de centrale à béton de mélange prêt

- concasseur utilise dans les ventes

- carriere dans la montagne

- conception dusine de concassage de pierre de 25 tph

- Jones modèle Shipman 1310 de la machine de meulage de précision

- rectifieuse coulissante

- court concasseur à cône de tête occasion à vendre

- autoclave broyeur béton cellulaire