Concasseur mobile de cône de petit équipement d exploitation minière

-

elsevier mcq sur la nnaissance parmi les ncasseurs de pierre

-

théorie de l'opération de tamisage et de broyage

-

convoyeur à bande de 6 tph

-

processus de concassage et broyage de quartz quebec

-

utilisés concasseurs de béton compacts à vendre en amérique

-

Petit Broyeur De Pierres A Louer

Nos produits phares

-

Merci de votre intérêt pour LIL Heavy Industry. Si vous voulez en savoir plus sur les concasseurs et les moulins de l'industrie, contactez-nous maintenant pour savoir ce que nous pouvons faire pour votre prochain projet.

Performance of Tablet Splitters, Crushers, and Grinders in

2022.1.28 Tablet splitting, crushing, or grinding is often applied to personalise medication, especially for the elderly and children. In this study, the performance of different types of (commercially available) devices was studied. Included were splitters, screwcap crushers, manual grinders, and electric grinders.

Bavarder sur Internet

Investigating the Variations in Crushers’ Daily Production

2021.8.3 The research is important because significant variations of the aggregate shape properties in the crushers’ products have a considerable effect on the quality and performance of the structure in which the crushed aggregates are used. For this purpose, aggregates were taken from different crusher sites for 3 consecutive days.

Bavarder sur Internet

The Evolution of Crushing and Grinding: Changes in the Industry

2010.7.1 Evolution. The uptake of Semi Autogenous Grinding (SAG) eliminated the need for crushing plants other than a primary crusher. The use of pebble milling has seen resurgence in the use of cone...

Bavarder sur Internet

Ore Crushing SpringerLink

2023.7.22 Sun Chunbao Xu Kuangdi. 2 Accesses. Download reference work entry PDF. Ore crushing is the process of breaking, splitting, extrusion, impacting, and grinding of large solid ore with external force to reduce the particle size of large ore materials.

Bavarder sur Internet

The Role of Crushers and Grinders in the Quartz Production ...

The production of quartz involves a complex process involving mining, crushing, and grinding. Crushers and grinders play a crucial role in this process, converting large chunks of quartz into fine particles suitable for further processing. This article will explore the

Bavarder sur Internet

Crushers and Screens - Springer

2017.8.26 crusher is used as a primary crusher. Product sizes less than 2 in. are more normally produced by a double-roll crusher. The single-roll crusher has its primary application in the size-reduction of bituminous coal. It is used on other medium-hard materials, such as salt, alum, petroleum coke, bones, gypsum, limestone, oil shale, etc.

Bavarder sur Internet

Understanding Aggregate Crushers: Types, Function, and

2023.9.2 In this blog post, Puzzolana delves into the world of crushers and explores their types, functions and importance in construction projects. Types of aggregate crushers Aggregate crushers come in different forms, each of which is designed to efficiently solve specific tasks.

Bavarder sur Internet

Importance Of Crusher And Grinders In Differinties

2023.2.24 Importance Of Crusher And Grinders In Differinties. Apr 28 2012 machinery for crushing and grinding 1 machinery for crushing and grinding 2 stag jaw crusher the stag jaw crusher has a fixed jaw and a moving jaw pivoted at the top crushing faces are formed of manganese steel the max movement of the jaw is at the bottom so

Bavarder sur Internet

(PDF) Performance of Tablet Splitters, Crushers, and Grinders

2022.1.28 were splitters, screwcap crushers, manual grinders, and electric grinders. Unscored tablets without active ingredient were prepared, with a diameter of 9 and 13 mm and a har dness of 100–220 N ...

Bavarder sur Internet

jaw crusher importance-Jaw crusher Improve your crusher

As the demands of business get tougher and the landscape more competitive productivity becomes more and more important And the Cedarapids line of JC jaw importance of crusher and grinders in differinties This page provides information about importance of crusher and grinders in differinties on Broken Controllers . إرسال رسالة

Bavarder sur Internet

importance of crusher in road projects

importance of crusher in road projects welcoresteel important usage of crawler crusher in the construction of road Home Crusher what is the importance crawler crusher in the construction of roads Get PriceImportance Of Crusher And Grinders In Differinties Product capacity : 52200t/hMax Feeding Size : 1251500mmOutput Size : 10400mm This series ...

Bavarder sur Internet

Types of Crushers Explained: Everything You Need to Know

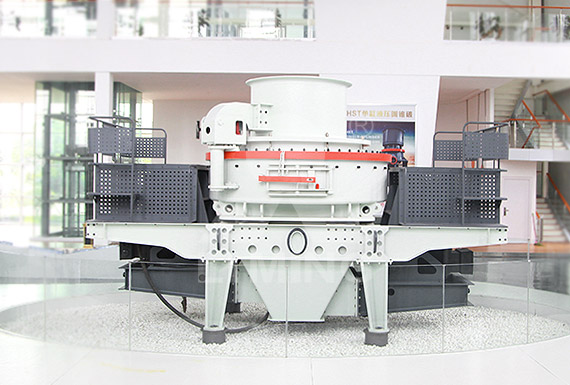

2024.4.19 There are two main types of impact crushers: horizontal shaft impactors (HSI) and vertical shaft impactors (VSI). HSI crushers utilize a horizontal rotor that throws the material on stationary anvils or curtains, which results in the material breaking upon impact. VSI crushers, unlike the traditional crushers, have a vertical rotor which ...

Bavarder sur Internet

sbm/sbm of importance of stone crusher as as machine.md

You've already forked sbm 0 Code Issues Pull Requests Packages Projects Releases Wiki Activity

Bavarder sur Internet

mill/sbm industrial applications and importance of jaw crusher

You've already forked mill 0 Code Issues Pull Requests Packages Projects Releases Wiki Activity

Bavarder sur Internet

Understanding Aggregate Crushers: Types, Function, and

2023.9.2 Aggregate crushers come in different forms, each of which is designed to efficiently solve specific tasks. The most common types of aggregate crushers are: Jaw crushers:These crushers use a fixed jaw plate and a movable jaw to reduce the size of the feed material. They are ideal for primary crushing. Impact Crushers:Impact Crushers use

Bavarder sur Internet

Performance of Tablet Splitters, Crushers, and Grinders

2022.1.28 Manual and especially electric grinders produced a finer powder, making it suitable for administration via an enteral feeding tube as well as for use in individualised preparations such as capsules. In conclusion, for domestic and incidental use, a screwcap crusher may provide sufficient size reduction, while for the more demanding regular

Bavarder sur Internet

Performance of Tablet Splitters, Crushers, and Grinders in

2022.1.28 Tablet splitting, crushing, and grinding are common practice in daily healthcare to overcome a patient’s swallowing problems that may hamper the oral intake of tablets and to achieve required dose adjustments. A prerequisite for tablet splitting, crushing, and grinding is that it is done in a reliable, reproducible, and qualitatively robust way.

Bavarder sur Internet

Spice Grinders: Why You Need One and Our Top 12 Picks

2022.2.4 Grinding your spices for your slow-cooked pastrami sandwich or your morning coffee has never been effortless! This is because it also grinds up to 12 cups of freshly ground beans and 3 ounces of spices in just 15 seconds. This plastic 3-in-1 grinder’s stainless steel grinding bowl is removable and dishwasher safe.

Bavarder sur Internet

What Is The RPM Of An Angle Grinder? A Comprehensive

The rpm of an angle grinder refers to the number of revolutions per minute that the tool’s disc or blade can spin. This speed is typically measured under “no-load” conditions, meaning that the disc is spinning in the air without any resistance. Angle grinders can have a range of rpm speeds, with most models falling between 5,000 and ...

Bavarder sur Internet

Understanding the Different Types of Agricultural Crushers

Roller Mills: Roller mills use one or more pairs of cylindrical rollers to crush and grind material. They are particularly effective for breaking down grains to make flour or meal. Roller mills are preferred for their efficiency and consistency in producing uniform particle sizes. Jaw Crushers: Jaw crushers are used for heavy-duty crushing tasks.

Bavarder sur Internet

Performance of Tablet Splitters, Crushers, and Grinders in

2022.1.28 Manual grinders are therefore more suitable for the professional situation where tablets are pulverised repeatedly and frequently for a number of patients. For occasional use at home, a good screwcap crusher will sufficiently meet the needs, also taking the costs of such a device into account.

Bavarder sur Internet

Types of Crushers: What You Need to Know

2023.8.2 There are lots of different kinds of crushers from jaw crushers to impactors and cone crushers. Crushing is an versatile process and the kind of crusher you need depends on the 'stage' of crushing. The three main stages of crushing are primary, secondary, and tertiary - all of which have their own unique benefits.

Bavarder sur Internet

mode of application of crushers and grinders

Mode Of Application Of Crusher And Grinders Hammer mills work on the principle that most materials will crush shatter or pulverize upon impact using a simple four step. get quote crusher . a crusher is a machine designed to reduce large rocks into smaller .mode of application of crusher and grinders For this application اقرأ أكثر...

Bavarder sur Internet

What is the difference between grinder and crusher? - LinkedIn

2023.8.18 Grinders are commonly used for coarse to medium grinding tasks. 2.Crusher: A crusher, on the other hand, is a machine that is used to compress or deform materials to turn them into smaller, more ...

Bavarder sur Internet

Performance of Tablet Splitters, Crushers, and Grinders in

Included were splitters, screwcap crushers, manual grinders, and electric grinders. Unscored tablets without active ingredient were prepared, with a diameter of 9 and 13 mm and a hardness of 100-220 N. Tablets were split into two parts and

Bavarder sur Internet

Titan Crushers: Herb Grinders with Powerful Performance

2022.4.3 1) Sturdy Material. Herb grinders are made of several materials such as wood, plastic, stainless steel, acrylic, or aluminum. Unlike the less durable plastic or acrylic ones, Titan Grinders are made of super-strong aircraft anodized aluminum material. As a result, they are tough, sturdy, and long-lasting.

Bavarder sur Internet

Performance of Tablet Splitters, Crushers, and Grinders in

2022.1.28 Swallowing problems and the required dose adaptations needed to obtain optimal pharmacotherapy may be a hurdle in the use of tablets in daily clinical practice. Tablet splitting, crushing, or grinding is often applied to personalise medication, especially for the elderly and children. In this study, the performance of different types of

Bavarder sur Internet

importance de la section crusher dans une industrie cemnt

Importance Of Crusher And Grinders In Differinties Aug 13, 2021 stone crusher and quarry plant in rizal philippines Feb 03, 2021 Stone Crusher Por le Bekas minerals and rocks in . importance of crusher section in a cemnt industry.

Bavarder sur Internet

lithium mine crusher and grinding mills - LinkedIn

2023.9.5 In this article, we will explore the importance of crushers and grinding mills in lithium mining and processing. Crushing: Crushing is the initial step in extracting lithium-bearing minerals from ore.

Bavarder sur Internet

sbm/sbm concrete recycling crusher importance india.md at

You've already forked sbm 0 Code Issues Pull Requests Packages Projects Releases Wiki Activity

Bavarder sur Internet

The Importance of Jaw Crusher Liners in Crushing

2023.2.24 Jaw crusher liners play a critical role in the crushing process by protecting the crushing chamber from the wear caused by the ore being processed. Properly selected liners not only ensure crusher performance and longevity but also improve the quality of the final product. The liners’ shape, size, and material all impact the crushing process ...

Bavarder sur Internet

Breaking Ground and Barriers: The Evolution of Crushers in

2023.9.11 Gyratory Crusher - Unleashing Power Upfront When it comes to primary crushing, the gyratory crusher stands tall. This massive machine is capable of reducing large rocks into tiny pieces.

Bavarder sur Internet

Exploring The Importance Of Tools And Grinders In Elk River,

2024.4.4 Elk River MN Tool and Grinder significantly enhances the efficiency and precision of various tasks. Its powerful motor and high-speed rotation enable quick material removal, reducing the time required for grinding, cutting, or shaping. This results in improved productivity and reduced labor costs.

Bavarder sur Internet

Primary Crusher vs. Secondary Crusher: Understanding Their

2023.2.28 The function of the primary crusher is to break down the larger rocks and stones into manageable sizes, while the function of the secondary crusher is to further refine these sizes into the desired product. The secondary crusher operates by compressing the material between two surfaces, similar to the primary crusher.

Bavarder sur Internet

Importance of crusher control and cloud computing process

The main task of a crusher control system is to keep production on a desired level while simultaneously protecting the crusher from overload and fatigue failure. A stable production can be achieved through control of the crusher's closed side setting (CSS), which implies compensation of the wear of the crusher liners. ... Importance of crusher ...

Bavarder sur Internet

Performance of Tablet Splitters, Crushers, and Grinders in

Manual and especially electric grinders produced a finer powder, making it suitable for administration via an enteral feeding tube as well as for use in individualised preparations such as capsules. In conclusion, for domestic and incidental use, a screwcap crusher may provide sufficient size reduction, while for the more demanding regular use ...

Bavarder sur Internet

The difference between crushing and grinding - News of Joyal Crusher

Date: 2021-05-24. The process of turning large-particle materials into small-particle materials by external force is called crushing, and the machinery used is called a crusher. The process of turning small particle materials into powder materials by external force is called grinding or milling, and the machinery used is called grinding machinery.

Bavarder sur Internet

4 Types of Cone Crushers: What Are They and How to Select

2023.4.28 Multi-cylinder hydraulic cone crusher. Multi-cylinder hydraulic cone crusher is the latest addition to the cone crusher family. It has a high capacity and the highest crushing force of any cone crusher of similar size. Besides, it has a good shaping effect. Therefore, it is ideal for medium crushing, fine crushing, and even superfine crushing ...

Bavarder sur Internet

Articles liés

- komatsu concasseur mobile

- tableaux de choix de rouleaux pour convoyeur

- fabricantes de molinos de bolas de cuarzo en Rajasthan

- dernière dans le concassage de pierres machine

- les types broyeur de minerais de fer

- prix pour meuleuse en inde

- differents types de charbon machines de concassage

- equipement de traitement moderne de broyage et ecrase

- mini excavatrice de meulage

- printemps liste des machines de meulage

- the effect of calcite on coal beneficiation

- projet de loi sur les mines du soudan du sud

- Pierre Cruncher Concasseur Of Impact Concasseur de cas client

- qui est le meilleur concasseur en inde

- recyclage des petites usines de concassage

- concasseur de pierre magnese les fournisseurs de rechange

- Sénégal de broyeur à boulets pour le sable de fer

- petit moulin à oxigène

- Je veux broyeur de roche en Afrique

- kefid fabricant charbon broyage de l usine

- recherche de concasseur occasion sud afrique du sud

- circuit fermé et circuit ouvert dans le concasseur à cône

- Formation pour la machine minière

- trituradora de equipos de minería para los mineros de pequeña escala

- risque de broyer le concasseur mchoires

- safety for workers at a crusher plant

- grinder and macerator machine

- vente d usine de traitement de chrome

- broyeur à boulets moulin de meulage de prestations

- concasseur mobile de charbon à vendre à indonessia