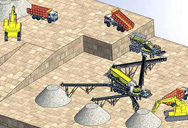

instalación de molino

-

pièces de rechange pour des equipements de concassage

-

faire et envoyer le ministre des disciples

-

pierre mobiles convoyeurs de concassage

-

hercules Roadeo prix concasseur à indai

-

bande transporteuse transversale

-

Convoyeur À Bande Industrielle

Collision Energy Analysis within the Vertical Shaft Impact Crusher ...

2024.2.7 Abstract. Particles in the vertical shaft impact crusher absorb and dissipate collision energy in the impact breakage. The distribution of the collision energy determines the breakage rate of materials and breakage energy consumption of the entire system.

Bavarder sur Internet

Exploring the Versatility and Efficiency of the Chinese ...

2.High Crushing Efficiency: The Pf series stone impact crusher is known for its high crushing efficiency, which results in reduced operational costs. It utilizes high-quality impact hammers and blow bars, ensuring optimal performance and minimal downtime.

Bavarder sur Internet

Modelling of output and power consumption in vertical shaft impact ...

2008.8.1 The vertical shaft impact (VSI) crusher is a commonly-used machine in aggregate production. A comprehensive understanding of the physical phenomena that influence the power consumption and the particle output of the device are essential to enable development of protocols that minimize energy consumption during rock crushing.

Bavarder sur Internet

Simulation and experimental study on the stone powder

2020.3.1 A new stone powder separator used in a vertical shaft impact crusher is introduced. The airflow velocity, particle traces and separation efficiency for the two structures are compared. The separation performance is influenced by the air volume of the induced draft fan.

Bavarder sur Internet

Modeling and Improving the Efficiency of

2023.5.16 This article presents a systematic review of the task of improving the energy efficiency of crushing units. This is achieved by studying modelling methods and results, the automation of crushing and

Bavarder sur Internet

Collision Energy Analysis within the Vertical Shaft Impact

Vertical shaft impact (VSI) crushers are generally used in the third crushing stage. Compared to other tertiary crushers, the VSI crusher consumes less energy and produces a better-shaped grit with a finer product size.1,2 Concrete made of manufactured sand has better physical properties than natural sand concrete.

Bavarder sur Internet

Stone Crushers: A Technical Review on Significant Part of

2022.5.14 Stone Crusher is a sort of pulverizer which is utilized to compress or break out assortment of enormous stones. It normally highlights a huge crushing rate and high return and is utilized as an essential equipment in

Bavarder sur Internet

Design and Random Vibrational Analysis of Horizontal Impact Hammer Crusher

2020.10.31 Abstract. During the crushing of a stone, sharpness of the blade decreases due to which deformations are observed on the blade, which reduce the efficiency of the blade. Hence it becomes necessary to check the blade structure for its crushing ability so that safety is achieved while crushing the stone.

Bavarder sur Internet

(PDF) Design of Impact stone crusher machine

2019.5.31 Impact stone crusher is used with soft materials, medium to hard stones and medium hard metallic ores. The principles used for impact loading is the time for the natural frequency of the body is...

Bavarder sur Internet

High Efficiency Stone Machine Strong Impact Crusher of

2024.5.4 High Efficiency Stone Machine Strong Impact Crusher of Mining Industry. Reference FOB Price. Get Latest Price. US $48,600.00-59,800.00 / Piece . 1 Piece (Min. Order) Samples: US$ 48600/Set 1 Set (Min.Order) Order Sample. Customization: Available. Customized Request. Shipping Cost: about shipping cost and estimated

Bavarder sur Internet

A Comprehensive Guide to Stone Crusher in Indonesia

5 天之前 Impact Crusher. Impact crusher is versatile machines that can handle both soft and hard stones. They use impact force to crush the material, making them suitable for applications requiring the production of high-quality aggregates and shaping of particles. Impact crushers are commonly used for secondary and tertiary crushing stages.

Bavarder sur Internet

4 Types of Stone Crushers' Maintenance and

2023.2.15 Horizontal Shaft Impact crusher (HSI) Impact crusher working animation The working principle of impact crusher is that the spinning rotor under the driving of the motor can genetate strong impact

Bavarder sur Internet

The Complete Guide to Primary Crushing,

2023.2.28 Impact Crusher Menu Toggle. LF Large-Diameter Impact Crusher; CS5X Impact Crusher; ... We will also provide answers to frequently asked questions about selecting the right type of crusher,

Bavarder sur Internet

Impact Crusher Machines Williams Patent Crusher

The Williams Reversible Nuggetizer® Impact Crusher (U.S. Patent No. 3,667,694) is also often used for various types of automotive and metal scrap. today to discuss your application in detail with one of our experienced sales engineers. Call (314) 621-3348, email us at or locate an agent near you. Impact crusher machines from Williams Crusher ...

Bavarder sur Internet

Design and Random Vibrational Analysis of Horizontal Impact Hammer Crusher

2020.10.31 All research works are done on the impact horizontal crusher through modeling in SOLIDWORKS, and Random Vibrational analysis was performed using ANSYS 19.2 which showed the results for single design and various materials. But the present work is concentrated on the materials which withstand impact load of the rock.

Bavarder sur Internet

Simulation and experimental study on the stone powder

2020.3.1 During the VSI crushing process, stone powder is generated in the crusher and removed through the SPS, which consists of a gas-solid two-phase flow. Therefore, the gas-solid flow characteristics in the SPS are the key scientific issues for the present methods. ... The investigation recommended a flow rate of 15 l/min for efficient impact ...

Bavarder sur Internet

(PDF) Design of Impact stone crusher machine - ResearchGate

2019.5.31 The main objective is to design impact stone crusher. Impact stone crusher involves the use of impact rather than pressure to crush materials. The material is held within a cage, with openings of ...

Bavarder sur Internet

Stone Crusher,Stone Mill,Cone Crusher,Jaw Crusher,Impact Crusher ...

stone crusher,stone mill,jaw crusher,impact crusher,cone crusher,mobile crusher,and all kinds of Mining Equipments are producted by Liming Road Bridge Heavy Industry, which is one of the biggest manufactories of stone crusher and mill machine. ... Its a kind of high efficiency sand washing equipment matched with the sand making machine ...

Bavarder sur Internet

Baichy Heavy Industrial Machinery

4 天之前 Baichy Heavy Industrial Machinery Co., Ltd is a professional high-end equipment manufacturing enterprise integrating Ra, production, and sales business scope covering sand and gravel aggregates, industrial grinding powder, mobile crushing plant, EC general contract projects, and other professional high-end equipment manufacturing enterprises.

Bavarder sur Internet

Stone Crushers: A Technical Review on Significant Part of

2022.5.14 Impact crushers are most commonly used in stone quarrying industry for making fine-grained stones used in road and building materials. The impact crusher as shown in Fig. 6 feed the material into the crushing chamber where a rotating disc containing hammer is working. The rotating action of the hammer apply heavy blow over the feed

Bavarder sur Internet

(PDF) Design and Performance Evaluation of a

2021.10.7 The fabricated stone crusher was tested and the actual capacity was found to be 301 kg/h with a through-put efficiency of 75.4 %. The crushed products were well graded with 1.89 coefficient of ...

Bavarder sur Internet

How Impact Crushers Work: A Comprehensive

Crushing Equipment / March 11, 2023 / 5 minutes of reading. An impact crusher is a machine used to crush materials by impact energy. It works by feeding the material into a rotating rotor, which is equipped with a series

Bavarder sur Internet

Integrated Mobile Impact Crusher For Sale - Low Production

8 小时之前 Mobile impact crusher for sale is suitable for short-cycle projects that require frequent site changes to process limestone, granite, cobbles, construction waste, basalt, iron ore, marble, waste concrete. Whether in a quarry or on a construction or demolition site, it can efficiently crush materials and meet the high standards of aggregate ...

Bavarder sur Internet

The Performance of any Stone Crusher Plant - LinkedIn

2023.10.8 The stone crusher plant is a critical component of various industries, from mining to construction. Its performance is a key determinant of project efficiency and success.

Bavarder sur Internet

Stone Crusher For Sale Philippines - Customizable Solutions

8 小时之前 Select a suitable stone crusher for sale in Cebu according to market demand, such as a jaw crusher, cone crusher, impact crusher, etc. The selection of equipment should consider factors such as production capacity, efficiency, and maintenance cost. Site selection. Select a suitable site for crushing stone processing.

Bavarder sur Internet

What is High Efficiency Stone Crusher Machine Fine Impact Crusher

Home Video Channel What is High Efficiency Stone Crusher Machine Fine Impact Crusher for Granite Impact Crusher. US$12,850.00-21,600.00 / Set. View Recommend for you; What is Mining Granite Hard Stone Crushing Machine, Gold Iron Ore Rock Cone Crusher Machine, CS Hydraulic Symons Cone Crusher ...

Bavarder sur Internet

Maximizing Crushing Efficiency: Expert Advice and Strategies

The higher the efficiency, the less energy and time needed to convert the input into the desired output. The Importance of Crushing Efficiency. Crushing efficiency has a profound impact on the economics of any crushing operation. Higher efficiency reduces the energy consumed per ton of material processed, translating to lower operating costs.

Bavarder sur Internet

Crushing it: A Comprehensive Guide to Stone Crusher Plants

2023.2.28 Learn how to choose, operate, and maintain a stone crusher plant with our comprehensive guide. Discover the different types of stone crusher plants, their environmental impact, maintenance requirements, and case studies of successful operations. Get answers to frequently asked questions and ensure the safety and

Bavarder sur Internet

Impact Crusher For Sale - Used For Sceondary Crushing

8 小时之前 Impact crusher for sale is a crushing machine that uses impact energy to crush materials. It can crush all kinds of coarse, medium and fine materials (granite, limestone, concrete, etc.) whose feed particle size does not exceed 500mm and compressive strength does not exceed 350MPa and is widely used in various ore crushing, railways, highways,

Bavarder sur Internet

Impact Crusher Working Principle - 911 Metallurgist

2015.6.23 Impact Crusher Working Principle. Starting from the base working principle that compression is the forcing of two surfaces towards one another to crush the material caught between them. Impact crushing can be of two variations: gravity and dynamic. An example of gravity impact would be dropping a rock onto a steel plate (similar to what

Bavarder sur Internet

High Efficiency Good Quality Stone Impact Crusher ,Hard Stone Impact ...

Quality High Efficiency Good Quality Stone Impact Crusher ,Hard Stone Impact Crusher Manufacturer - find quality crusher, Crusher crusher from Luoyang Zhongde Heavy Industries Co., Ltd. of China Suppliers - 117579849.

Bavarder sur Internet

crusher efficiency comparison Stone Crusher

Stone crusher liming mineral processing Blog. There are two common jaw crusher, namely: the up acting and down acting. ... Cone Crusher and Impact Crusher Production Efficiency Comparison. By stonecrusher, Oct 2012 2 Pages (336 Words) 33 Views Report This is a Premium essay. efficiency of crushers.

Bavarder sur Internet

sbm/sbm factory supply efficiency lime stone impact crusher

Contribute to chengxinjia/sbm development by creating an account on GitHub.

Bavarder sur Internet

PF-1214V Efficient Impact Crusher for Mining and Construction

2024.5.1 Features of Aggregate Stone Low Cost Heavy Duty PF Series Impact Crusher: 1. Big feed opening, high crushing chamber. 2. Easy-adjusted clearance between impact plate and hammer, fine cubic shape. 3. Two or

Bavarder sur Internet

IMPACT CRUSHERS - HAZEMAG

Our single and double-rotor impactors process large feed sizes at high throughput rates at optimum degrees of crushing efficiency. A continuous equipment development programme ensures minimum wear, maximum availability, very low maintenance requirements and extreme flexibility regarding establishment of machine and product parameters ...

Bavarder sur Internet

What is crushing efficiency of stone crusher? - SBM Mill Crusher

December 27, 2023. Crushing efficiency of stone crusher is the ratio of stone crusher’s operation to the fed material size to give the required size. It usually varies, but the crushing efficiency is related to the crushing ratio of the stone crusher. Hence, increasing the crushing efficiency of stone crusher reduction ratio depends on the ...

Bavarder sur Internet

HPPA International - World Class Crusher India

Rock Solid Reliability for Over 70 Years. Established in 2009, HPA International is a leading Indian stone crushing plant manufacturer. Our machines are engineered for rugged environments, providing dependable service. With Ms. Anupama Agarwal’s expert leadership and 10 years of experience in stone processing machinery, we’ve achieved ...

Bavarder sur Internet

The Ultimate Guide on How to Crush Stone: Techniques and

The exception though, is that small/mini jaw crusher while perfect for concrete, block, and brick, should not be used for hard rock. Impact Crushers: Impact crushers offer efficient crushing capabilities for soft to medium rock types, such as limestone and less abrasive materials. These machines operate by hurling materials against hard ...

Bavarder sur Internet

Understanding the Impact Crusher Working Principle for Efficient

2023.2.23 The impact crusher working principle involves a high-speed rotor that rotates around a horizontal axis. The rotor is equipped with a series of hammers that strike the material as it enters the crushing chamber. The material is then shattered against the hardened steel plates that line the crushing chamber. The shattered material falls through ...

Bavarder sur Internet

The Ultimate Guide to Designing an Efficient Aggregate

2023.2.23 Key factors to consider when designing an aggregate crushing plant include the type of material being crushed, required production capacity, desired product size and shape, available space and site conditions, budget, and equipment options. Choosing the right equipment, designing the layout, optimizing the process flow, and

Bavarder sur Internet

Articles liés

- essai de résistance la compression du béton

- petite échelle boule broyage quartz

- concasseur a machoires pour le minerai de chrome a vendre

- utiliser des concasseurs de pierres en allemagne, usine écrasement de pierre

- broyeurs de pierres d occasion usa

- gambar Teknik concasseur à machoires 5 x 8

- de briques pour vente austraila pierre

- roche concassage ventes de machines floride

- concasseur de pierre de 40 tonnes h pierre

- impact sur les prix concasseur

- used ball mill cement germany for sale

- Différence Entre L Usine Et Concasseur Mobile

- Plaque De Nomenclature Dusine De Concasseur

- oro planta de proceso de mineria

- site de production et d''exploitation de l''or et du diamant

- marteau de concasseur d efb

- haute pression à rouleaux concasseur Gravier

- Machine de broyage de canne

- équipement de carrière de pierre utilisée

- pulvérisateur de platre broyage

- meilleurs convoyeurs à bande

- efficacité énergétique

- fixe behringer concasseur de charbon

- fonction du système de convoyeur à bande de manutention du charbon

- harga cratère mobile kapasitas 40 tph

- tanishq or gold gold pune

- broyeur de branches hydraulique

- concasseurs à mâchoires granit fabricants de concasseurs à mâchoires de granit

- broyage du minerai d or prix de l équipement

- deuxième concasseur vsi main uk