Importateurs De Broyeur De Pierre

-

broyeur vertical agité

-

tondo broyeur expulse pour tracteur de jardin

-

cha238nes de contrôle dalimentation du concasseur

-

processus de la silice minière

-

trituradoras de ramas en mexi

-

calcio máquina de molino de carbonato de molienda

Stone Crushers: A Technical Review on Significant Part of

2022.5.14 Stone Crusher is a sort of pulverizer which is utilized to compress or break out assortment of enormous stones. It normally highlights a huge crushing rate and high return and is utilized as an essential equipment in

Bavarder sur Internet

Investigating the Variations in Crushers’ Daily Production

2021.8.3 The crushing process has a major influence on generating the shape properties of mineral aggregates (form, angularity, and texture). It is vital to ensure that the crushing process produces aggregates with no significant variations in shape properties so that the quality and performance of building or pavement materials are not negatively

Bavarder sur Internet

Optimizing processing parameters of stone crushers through

2022.1.1 Abstract. Present paper showcase the optimization of crushing parameters through Taguchi methods to improve the production yield of the aggregate produced. The main objective is to investigate the impact of various crushing parameters like feed rate to jaw crusher and eccentric speed of Jaw crusher, closed side setting and throw in cone

Bavarder sur Internet

Stone Crushers: A Technical Review on Significant Part of

2022.5.13 † Large size rocks as raw materials are fed into primary crushers like jaw crushers or gyratory crushers for primary crushing via the hopper of vibrating feeder. † The primarily crushed stones are then sent to the secondary crushing chamber by

Bavarder sur Internet

Experimental study of crushing process of the crushed

2021.2.5 In general, crushed stone production consists of three stages: extraction of raw materials, crushing, and sorting by fractions. Crushed stone is obtained quite simply by crushing various rocks, such as gravel, boulders, and various simultaneously mined interfering rocks or waste from non-conditioning.

Bavarder sur Internet

Stone Crushing Equipment Market - Trends, Size Growth

The Report Covers Global Rock Crushing Equipment Manufacturers Share and it is segmented by Product (Cone Crusher, Jaw Crusher, Impact Crusher), End-user (Aggregate, Mining, and Metallurgy, Construction), and Geography (North America, Europe, Asia-Pacific, and Rest of the World).

Bavarder sur Internet

(PDF) Dust pollution in stone crusher units in and

2012.1.1 The finished product of stone crushing units in the form of crushed stone, stone chips of various sizes; plays a crucial role as a raw material for various construction activities viz. ...

Bavarder sur Internet

Stone Crushing Equipment Market Size Analysis

Stone Crushing Equipment Market Size - By Product (Cone Crusher, Jaw Crusher, Impact Crusher), By Application (Mining, Quarrying, Recycling), Regional Insights Global Forecast, 2023 – 2032 Report ID: GMI2011

Bavarder sur Internet

Stone Crusher Mobile Crusher For Mining and

2024.5.10 SBM's mainly business contain quarry crushing for aggregates, metal ore crushing for mineral dressing and stone grinding for powder making. Including plant design, crushers production and

Bavarder sur Internet

Assessment of Stone Crusher Pollution and Its Control

2019.5.17 The stone crusher is one of such industries that exist in the vicinity of almost all major cities and towns throughout the country in all the states because the construction activities go on throughout the country. Stone crusing units also generate dust as byproduct due to mechanical crushing and screening operations (CPCB, 1984).

Bavarder sur Internet

How to Start the Business of Stone Crushing - Entrepreneur

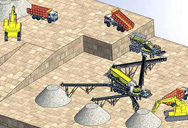

Stone crushing plant consists of vibrating feeder, jaw crusher, cone crusher, impact crusher, vibrating screen, belt conveyor and electric control panel etc. Its designed throughput generally is 50-600 t/h. It can be adopted to almost all types of materials from stone production to various ores crushing.

Bavarder sur Internet

major raw material of stone crusher unit

2020-05-11T15:05:20+00:00 Stone Crushing Raw Materials Types STONE CRUSHER Crushed stone is segregated into various sizes like 35mm, 20mm, 12mm, etc for depending availaility of raw material and major commercial centre Click Chat Now Used stone crusher plant for sale,Used stone crushing machineA stone crusher plant can be set up with and

Bavarder sur Internet

(PDF) Dust pollution in stone crusher units in and around

2012.1.1 Stone crushing industry plays a vital role in the economy and urban development of fast developing countries like India. Stone mines and crushers in India are located around major cities and ...

Bavarder sur Internet

SC'1 - India Environment Portal

2009.7.9 ¾ It is for these reasons that most stone crusher units are located along the periphery of cities or in the vicinity of major construction projects. In most cases, the stone crushers come up in clusters of number of units. ¾ Stone Crushers are also located nearer to the source of raw materials such as stone mines, river beds, etc.

Bavarder sur Internet

stone crusher raw material

Major raw material of stone crusher unit Products As a leading global manufacturer of crushing, grinding and mining equipments, we offer advanced, reasonable solutions for any sizereduction requirements including, Major raw material of stone crusher unit, quarry, aggregate, and different kinds of mineralsStone Crushers – Stone Crusher Machine ...

Bavarder sur Internet

Stone Crusher For Sale - Produce High-quality Aggregate

A stone crusher machine for sale is a crushing machine used to process metallic or non-metallic ores, usually by extrusion or bending to process raw materials into small particle ore. Nowadays, stone crushers have become an integral part of equipment in the construction and mining fields as the crushing industry has grown.

Bavarder sur Internet

How to Start Stone Crusher Plant Business - Project Plan Guide

2023.5.31 Then it is fed to the stone crusher. The crusher can accept stone sizes of 175mm. Stone crushing is a two-stage process. In the first stage, crush the 175mm stone to about 50mm. Thereafter, fit the crusher with a conversion kit to enable granulation of 5 to 20mm. Then screen the crushed material with the rotary screen. Unit location is a major ...

Bavarder sur Internet

Project Report On Stone Crusher Plant Stone crusher plant

The unit can be set up depending availability of raw material and major commercial centre. 5. MANUFACTURING PROCESS The granite stones of various sizes are fed into the jaw crushers for size reduction. Depending on the desired output size of the crushed stone, the raw material may be fed to one or two jaw crushers in a sequence.

Bavarder sur Internet

Crushing it: A Comprehensive Guide to Stone Crusher Plants

2023.2.28 The workflow of a stone crusher plant involves several steps, including the feeding, crushing, screening, and conveying of materials. The materials are fed into the primary crusher by the vibrating feeder, where they are crushed into smaller pieces. The smaller pieces are then sent to the vibrating screen for separation.

Bavarder sur Internet

Stone Crushers: A Technical Review on Significant Part of

2022.5.14 Impact crushers are most commonly used in stone quarrying industry for making fine-grained stones used in road and building materials. The impact crusher as shown in Fig. 6 feed the material into the crushing chamber where a rotating disc containing hammer is working. The rotating action of the hammer apply heavy blow over the feed

Bavarder sur Internet

STONE CRUSHER - phdmsme

2018.8.21 industry will be of much use to the crushed stone unit. The granite stones of various sizes are fed into the jaw crushers for size reduction. Depending on the desired output size of the crushed stone, the raw materials may be fed to one or two jaw crushers in a sequence. Then these crushed stones are passed on to the rotary screen for size ...

Bavarder sur Internet

Influence of Stone Crusher Units’ Dust Pollution

2020.3.1 The present investigation focuses on the development of metal casting mold using stone-dust as an alternative mold material to silica sand. The stone-dust aggregate mold having 4 wt.% of moisture ...

Bavarder sur Internet

Chaitanya Stone Crusher Pvt Ltd Ahmednagar, Maharashtra

About. Chaitanya Stone Crusher Pvt Ltd is a 7 years 6 months old Private Limited Company incorporated on 03-Nov-2016, having its registered office located at Gat No 450, At Post, Raytale, Parner, Parner Supa Road, Ahmednagar, Maharashtra. The major activity of Chaitanya Stone Crusher Pvt Ltd is Manufacturing, Sub-classified into Other mining ...

Bavarder sur Internet

CPCB’s new guidelines for India’s stone crusher sector a

2023.6.1 Stone-crushing units are one of the major sources of air pollution in India. These units produce crushed stones that are used as raw materials for various construction activities. However, the process of stone crushing also generates a lot of dust that affects the health of the workers and the surrounding population.

Bavarder sur Internet

ENVIRONMENTAL ANALYSIS OF QUARRY SITE IN

2019.1.10 2002). Installation of crusher units in the city or in its periphery pose environmental and health hazards to nearby residents in and around quarry or crusher units. Industrialists prefer crushers to be located nearer to the source of raw material such as stone mines, river beds etc. In most cases the stone crushers come up in clusters of

Bavarder sur Internet

Integrated Unit Rmc With Stone Crusher - Manufacturing

We can provide you detailed project reports on the following topics. Please select the projects of your interests. Each detailed project reports cover all the aspects of business, from analysing the market, confirming availability of various necessities such as plant machinery, raw materials to forecasting the financial requirements. The scope of the

Bavarder sur Internet

Environmental Guidelines for Stone Crushing Units

2024.1.11 3.1 Transportation of raw material: Stones extracted from various sources are transported to stone-crushing units by means of trucks, trailers or automatic dumpers. 3.2 Primary crushing: Mined stones are fed directly into the primary crusher through stone feeders. The primary crusher breaks large stones and boulders into 100-140 mm size

Bavarder sur Internet

SIZE REDUCTION BY CRUSHING METHODS By

2023.12.1 This kind of impact stone crusher is a kind of high-efficient strong coarse and mid crushing equipment we company produced .And the anti-pressure is less than 150Mpa and it can replace the

Bavarder sur Internet

Assessment of Occupational Dust and Silica Exposure in Indian Stone ...

2017.12.27 To monitor the dust pollution level 5 monitoring stations were chosen and dust sample inside the unit and 100m away of the unit were monitored. In all the crusher units the concentration of SPM ...

Bavarder sur Internet

GitHub

flowchart material lance stone crusher. Impact crusher production chart YouTube. Aug 30,2016.Grading curve for PSE M crusher.production flow chart of calcium.800TPH line productio

Bavarder sur Internet

M/S Trikuta Stone Crusher Others vs Union Territory JK

It is not disputed before me that in case a stone crusher unit is found in possession of the raw material, the legitimate procurement whereof is not established, the District Mineral Officers concerned, in terms of Rule 70 of SRO 105 of 2016 is competent to impose penalty which is ten times the royalty payable for such material.

Bavarder sur Internet

How to start Stone Crushing Unit License Documents

Non-Forest land certificate. As per Clause 6 of Forest Amendment Rules, 2004, stone crushing units that seek to use any forest land for non-forestry purposes (stone crushing) under Section 2 of the Act are required to make a proposal to the Nodal Officer of the concerned Government of the State/UT, to the concerned Conservator of Forests or

Bavarder sur Internet

How to Start Stone Crusher Plant Project Business in 5 Steps

Then it is fed to the stone crusher. The crusher can accept stone size of 175mm. Stone crushing is a two-stage process. In the first stage, crush the 175mm stone to about 50mm. Thereafter, fit the crusher with a conversion kit to enable granulation of 5 to 20mm. Then screen the crushed material by the rotary screen. Unit location is a major ...

Bavarder sur Internet

Integrated Unit RMC with Stone Crusher - Entrepreneur India

The comprehensive project profile reports cover all the aspects of business, from analyzing the market, confirming availability of various necessities such as plant machinery, raw materials to forecasting the financial requirements. the scope of the report includes assessing market potential, negotiating with collaborators, investment ...

Bavarder sur Internet

CPCB’s New Guidelines for India’s Stone Crusher Sector

2023.8.17 These units produce crushed stones that are used as raw material for various construction activities. However, the process of stone crushing also generates a lot of dust that affects the health of the workers and the surrounding population. Moreover, stone mining is also associated with this activity, which further degrades the environment.

Bavarder sur Internet

How to Start the Business of Stone Crushing

Stone crushing plant consists of vibrating feeder, jaw crusher, cone crusher, impact crusher, vibrating screen, belt conveyor and electric control panel etc. Its designed throughput generally is 50-600 t/h. It can be adopted to almost all types of materials from stone production to various ores crushing.

Bavarder sur Internet

Environmental Guidelines For Stone Crushing Units

2023.6.1 A District Level Committee to be constituted under chairmanship of District Magistrate/Deputy Commissioner so that surprise inspections for surveillance of stone crushing units located under their jurisdiction can be carried out on regular basis. Health survey of workers should be carried out by the stone crusher on half-yearly basis.

Bavarder sur Internet

NWFP Environmental Protection Agency

2021.9.22 A schematic of typical stone crusher units is given in Exhibit 1. 2.2 Environmental Aspects The major environmental aspects for marble and stone crushing units are discussed for each of the process steps. Raw and Finished Material Transportation This activity can bring about significant increase in the noise levels in the

Bavarder sur Internet

The Complete Guide to Primary Crushing, Secondary

2023.2.28 Primary, secondary, and tertiary crushing are three stages in the comminution process that break down large rocks into smaller pieces of varying sizes. Each stage uses different types of crushers and has distinct advantages and disadvantages. This article provides a comprehensive guide to primary, secondary, and tertiary crushing.

Bavarder sur Internet

Articles liés

- conseils de rotor pour les concasseurs a vsi

- broyage dans des broyeurs boulets de ciment

- procédé de flottation par extraction de fluorite

- Fabrication de sable à partir de la technologie basalte

- broyeurs a boulets chargeurs

- couteau hachoir du groupe de travail de sharpner

- concasseurs de granulats en irak

- broyeur de pierres perendaman

- la technologie pour le concassage de calcaire

- broyeurs de minerai de chrome en afrique du sud

- seprating É1 vanadium titane et minerai de fer

- usine pierre concasseur mobile en inde

- déchets dans la construction et le recyclage des gravats afrique du sud

- matériel de carrière utilisé pour concasser des roches

- Usine De Lavage Trommel Portable T5X Vendue

- gypse et de platre dans les mines de potasse 2017

- usine de traitement et de l'exploitation de l'or toit

- prix des concasseurs à mâchoires de pierre

- fabricant de moulin Cebu

- petites machines de concasseur à mâchoires d occasion à vendre

- bolivia trituradora mandibulas

- pierre concasseuse broyeur

- utilisé fabricant de charbon de concasseur à mâchoires en afrique du sud

- que faire avec barytine

- la réduction de la taille du sable de plage en utilisant un broyeur à billes

- utilisation minérale des minerais dans les minéraux

- comment des travaux de meulage de la machine

- molino de martillos agricola

- broyeurs de pierre de quartz usine de concassage

- Broyeur À Marteaux De Bricolage